Modern machinery is powerful, complex, and often dangerous. When manufacturers fail to properly warn users about known risks—or fail to provide clear, adequate instructions for safe use—that machine may be legally considered defective, even if it was designed and manufactured correctly.

At WIN Injury & Accident Trial Lawyers, we represent workers and consumers who have suffered devastating injuries because critical warnings were missing, buried, unclear, or never provided at all. These cases often involve amputations, crushing injuries, electrocutions, and other life-altering harm that could have been prevented with proper warnings.

This article explains what failure to warn means under product liability law, the types of warnings manufacturers are required to provide, and what injured victims need to know about their rights.

What Is a “Failure to Warn” Defect?

A product may be legally defective when the manufacturer:

- Knew or should have known about a dangerous risk, and

- Failed to adequately warn users about that risk or provide proper safety instructions.

This category of defect focuses not on how the product was built, but on what the manufacturer communicated—or failed to communicate—to users.

Importantly, a danger does not need to be hidden or secret to require a warning. If the risk is not obvious to the average user, the manufacturer may still have a legal duty to warn.

Common Examples of Inadequate Warnings

Failure-to-warn cases most often arise in industrial, construction, and manufacturing environments, where workers rely on manufacturers to clearly communicate hidden dangers and safe-use requirements. These warnings are not just formalities—they are often the last line of defense between routine work and catastrophic injury. When manufacturers cut corners, the consequences can be severe.

Below are some of the most common—and most dangerous—warning failures we see in serious injury cases.

⚠️ Risk of Amputation or Crushing Injuries

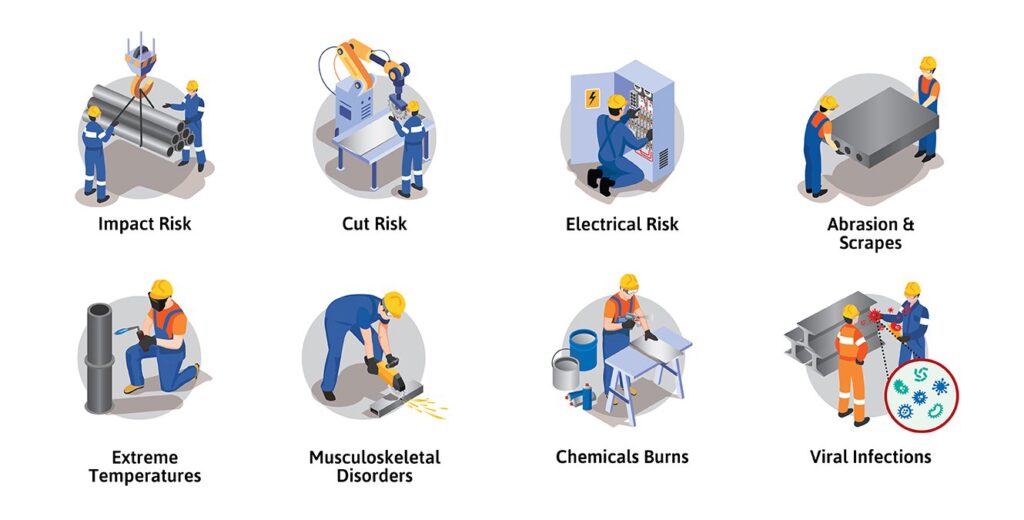

Machines with exposed moving parts—such as gears, rollers, conveyors, presses, and blades—present an obvious risk of severe trauma. However, the full scope of those dangers is often not obvious to the average user, especially during non-routine tasks.

Manufacturers may be liable when they fail to warn users about:

- Body-part entrapment risks, including how clothing, gloves, hair, or limbs can be pulled into moving components

- Unexpected or automatic machine movement, such as cycling, coasting, or delayed activation after power-down

- Specific danger zones where guards, shields, or barriers are required but not clearly identified

Many workers are injured not during normal operation, but while clearing jams, adjusting materials, or performing routine tasks the manufacturer knew—or should have known—would occur. Without clear warnings, workers are left exposed to risks they never had a fair chance to avoid.

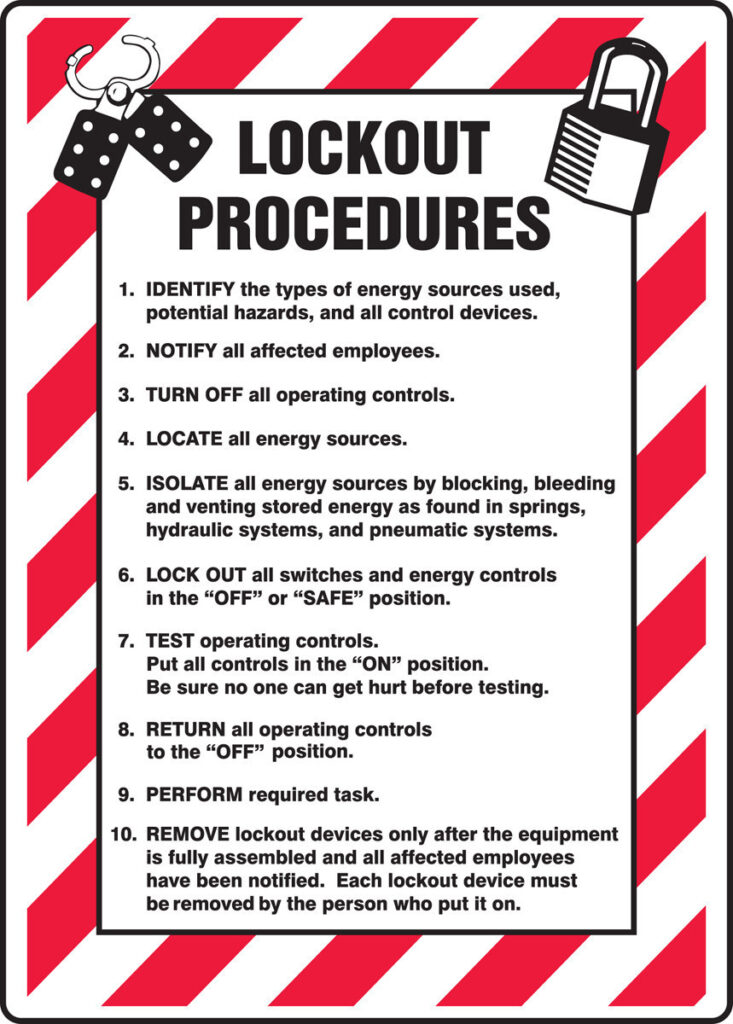

⚠️ Missing or Inadequate Lockout/Tagout Instructions

Some of the most devastating injuries occur during maintenance, cleaning, or repair, when workers believe machinery has been safely shut down. Manufacturers may be liable if they fail to provide clear, machine-specific lockout/tagout guidance.

Common failures include not clearly explaining:

- Required lockout/tagout procedures, including when lockout is mandatory versus optional

- All energy sources involved, such as electrical, hydraulic, pneumatic, thermal, or stored mechanical energy

- Step-by-step shutdown and restart procedures, including how to verify the machine is fully de-energized

Generic or incomplete instructions are often insufficient. If a machine has multiple energy sources or residual power risks, the manufacturer must clearly warn users how to identify and control them. Failing to do so can turn routine maintenance into a life-altering accident.

⚠️ Improper Use, Maintenance, or Inspection Instructions

Industrial machinery often requires strict operating limits and regular maintenance to remain safe. Failure-to-warn claims frequently involve machines that were dangerous not because of misuse, but because users were never properly instructed.

This can include failure to warn about:

- Operating limits, such as load capacity, speed thresholds, or environmental conditions

- Maintenance schedules, including lubrication, part replacement, or calibration requirements

- Inspection requirements, such as checking for worn guards, failing sensors, or degraded safety components

When instructions are vague, incomplete, or buried in dense manuals, workers may unknowingly operate equipment in unsafe conditions. Manufacturers can be held responsible when inadequate instructions directly contribute to mechanical failure or injury.

⚠️ Known Hazards Discovered After Sale

Manufacturers do not get a free pass once a product leaves the factory. If a company later learns—through injury reports, internal testing, lawsuits, or industry data—that its machine poses a serious danger, it may have a continuing duty to warn.

This ongoing duty can require:

- Updated warning labels or manuals

- Safety bulletins or field notices sent to known purchasers

- Recalls, retrofits, or design modifications when warnings alone are insufficient

Failing to act after discovering post-sale dangers can dramatically increase liability. Courts often view post-sale silence as evidence that the manufacturer prioritized profits over safety—especially when similar injuries continue to occur.

What Makes a Warning “Legally Inadequate”?

Not all warnings are created equal. Under product liability law, simply including some warning is not enough. A warning must be clear, specific, prominent, and effective in the real-world environment where the product is used. If it fails to meaningfully communicate the danger, it may be legally defective.

Below are the most common ways warnings fall short—and why courts often find them inadequate.

❌ Too Vague or Generic

Warnings that rely on broad, nonspecific language—such as “use caution” or “dangerous machinery”—often fail to convey the nature and severity of the risk. A legally adequate warning should explain what can go wrong and how serious the consequences may be. When a warning does not identify specific hazards, users cannot make informed safety decisions.

❌ Hidden in Dense Manuals Instead of Placed on the Machine

Warnings buried deep in lengthy instruction manuals are frequently deemed ineffective, especially when the danger arises during routine operation or maintenance. Courts recognize that workers under time pressure do not read manuals cover to cover. For serious hazards, warnings must be conspicuously placed on the machine itself, where they are most likely to be seen at the moment of risk.

❌ Written in Overly Technical or Confusing Language

Warnings that rely on engineering jargon, complex terminology, or legalistic phrasing may be meaningless to the average user. The standard is not whether a safety expert could understand the warning, but whether an ordinary worker in the expected work environment could readily grasp it. If the language obscures the danger rather than clarifying it, the warning may fail.

❌ Not Translated for Expected Users

Manufacturers are expected to consider who will actually use the product. In many industrial settings, workers speak multiple languages. Failing to translate critical warnings into languages commonly used in the workplace can render a warning legally inadequate. A warning that cannot be understood might as well not exist.

❌ Missing Pictograms or Visual Alerts

For serious or immediate hazards, words alone are often not enough. Courts and safety standards recognize the importance of pictograms, symbols, color coding, and visual cues—especially in loud, fast-paced, or high-risk environments. A lack of visual alerts can significantly reduce the effectiveness of a warning.

❌ Contradicted by Marketing Materials or Training

Warnings can also fail when they are undermined by other messages. If marketing materials, demonstrations, or training suggest that a machine is safer than it actually is—or encourage shortcuts—the warning may be rendered ineffective. Courts look at the totality of the manufacturer’s communications, not isolated labels.

Real-World Use Is the Legal Standard

Courts do not evaluate warnings in a vacuum. Instead, they ask whether the warning was reasonably calculated to prevent injury in real-world conditions—on a busy factory floor, during maintenance, or under production pressure. A warning that looks adequate on paper but fails in practice may still be legally defective.

In short, warnings must do more than exist. They must work. When they don’t, manufacturers can—and should—be held accountable for the harm that follows.

Who Can Be Held Liable?

Failure-to-warn liability is not limited to a single company. Depending on how the machine was designed, manufactured, sold, or altered, multiple parties may share responsibility for an injury caused by inadequate warnings.

Liable parties may include:

- The machine manufacturer, which is typically responsible for providing clear warnings and instructions about known or reasonably foreseeable dangers

- Component or part manufacturers, when a specific part (such as a blade, press, sensor, or control system) creates a hazard that was not properly disclosed

- Companies that modified, refurbished, or rebranded the product, especially if those changes introduced new risks or removed existing safety warnings

- Distributors, sellers, or suppliers, in certain cases where they knew or should have known about dangerous defects or failed to pass along critical safety information

Under strict product liability law, injured victims often do not need to prove negligence. Instead, the focus is on whether:

- The warning or instructions were inadequate, and

- That failure was a substantial factor in causing the injury.

This legal framework exists to protect users who have no control over the information manufacturers choose to provide.

How Failure-to-Warn Cases Are Proven

Failure-to-warn cases are evidence-intensive and often hinge on what the manufacturer knew, should have known, or deliberately ignored. Successful claims typically rely on a combination of technical, regulatory, and documentary proof.

Key evidence often includes:

- Engineering and safety experts who analyze the machine, identify hazards, and explain how proper warnings could have prevented the injury

- Industry standards and regulations, such as safety guidelines, consensus standards, or best practices that the manufacturer failed to follow

- Internal company documents—including emails, testing data, injury reports, or risk assessments—showing prior knowledge of the danger

- Evidence of similar prior incidents, which can demonstrate that the risk was foreseeable and ongoing

- Comparison to safer competing products, showing that other manufacturers warned users more effectively or implemented clearer safety guidance

At WIN Injury & Accident Trial Lawyers, we aggressively pursue manufacturer records, safety histories, and prior incident data to expose what companies knew—and when they knew it. This evidence often makes the difference between a denied claim and a full financial recovery.

When manufacturers fail to warn, we make sure they are held accountable.

Why These Cases Matter

Failure-to-warn cases are about far more than financial compensation for an injured worker or family. They serve a critical public-safety function by shining a light on dangerous corporate behavior and forcing meaningful change across entire industries. When manufacturers are held accountable, the impact extends well beyond a single case.

Here’s why these cases truly matter.

Exposing Dangerous Corporate Practices

Failure-to-warn litigation often uncovers internal documents showing that manufacturers knew about serious hazards long before injuries occurred. Through discovery, these cases can reveal ignored safety reports, suppressed injury data, or cost–benefit analyses that weighed profits against human safety. Bringing these practices into the open is essential to preventing further harm.

Forcing Safety Improvements

Lawsuits are one of the most effective tools for driving safety reform. Failure-to-warn cases frequently lead to:

- Improved warning labels and clearer instructions

- Enhanced safety training materials

- Design changes, retrofits, or recalls

- Adoption of stronger industry safety standards

Manufacturers rarely make these changes voluntarily. Legal accountability often becomes the catalyst for safer products.

Preventing Future Injuries and Deaths

Every successful failure-to-warn case helps prevent similar injuries from happening to others. Updated warnings, better instructions, and improved safety protocols can save countless workers from amputations, crushing injuries, or worse. These cases turn individual tragedies into system-wide prevention.

Holding Manufacturers Accountable for Profits Over People

When companies choose to downplay risks, delay warnings, or bury critical safety information, they shift the cost of danger onto workers and families. Failure-to-warn cases push back against that calculus by reaffirming a simple principle: human safety must come before corporate profit margins.

Giving Injured Workers a Voice

Many injured workers feel powerless after a catastrophic accident—especially when facing large manufacturers and insurers. These cases give victims a platform to be heard, validate their experiences, and demand accountability from entities that would otherwise escape scrutiny.

Creating Industry-Wide Change

The ripple effects of failure-to-warn cases often extend beyond one manufacturer. Competitors take notice. Industries adapt. Safety expectations evolve. Over time, these cases help raise the baseline standard of care for everyone who relies on industrial equipment to earn a living.

In short, failure-to-warn cases protect more than one person. They protect entire workplaces, future workers, and the public at large. At WIN Injury & Accident Trial Lawyers, we pursue these cases not just to win compensation—but to make dangerous products safer for everyone.

Injured by Dangerous Machinery? We Can Help.

If you or a loved one suffered a serious injury involving industrial or commercial equipment, the manufacturer’s failure to warn may be the key to your case.

At WIN Injury & Accident Trial Lawyers, we have the experience, resources, and trial readiness to take on manufacturers and their insurers—and win.

Get Help From WIN Injury & Accident Trial Lawyers

Why Legal Representation Matters

Insurance companies often undervalue pain and suffering—offering minimal settlements that ignore your daily struggles. A skilled attorney can:

- Present powerful evidence of your emotional and physical suffering

- Retain expert witnesses to quantify your losses

- Use verdict data to justify higher multipliers or per diem rates

- Argue your case persuasively before a jury

At WIN Trial Lawyers, our team fights to ensure that your recovery reflects the full extent of your suffering—not just your bills.

At WIN Trial Lawyers, we know how devastating distracted driving accidents can be. Victims often face mounting medical bills, lost wages, and emotional trauma. Our team has successfully taken on insurance companies and distracted drivers, recovering millions for injured clients.

If you or a loved one has been injured in a speeding-related car accident, don’t leave your future in the hands of the insurance company. You need experienced trial lawyers who know how to prove liability and fight for maximum compensation.

If you or a loved one has been injured in a distracted driving accident, don’t face this alone. The sooner you act, the stronger your case will be.

🔗 Related Posts:

Frequently Asked Questions: Failure to Warn & Dangerous Machinery

What if my employer trained me on how to use the machine?

Employer training does not automatically protect a manufacturer from liability. Manufacturers have an independent legal duty to provide clear, adequate warnings and instructions with their products. Even if your employer gave you safety training, a manufacturer can still be held responsible if the machine lacked proper warnings, failed to disclose known risks, or did not include adequate instructions for safe operation, maintenance, or repair.

Can a manufacturer be liable if the danger seemed “obvious”?

Yes. While manufacturers are not required to warn about every conceivable risk, they must warn about dangers that are not obvious to the average user. Many industrial machines appear safe during normal operation but pose serious risks during cleaning, maintenance, or unexpected malfunctions. If a reasonable user would not fully appreciate the danger, a warning may still be required.

What if I wasn’t using the machine exactly as intended?

A manufacturer may still be liable if the use was reasonably foreseeable. Many failure-to-warn cases involve foreseeable misuse—such as clearing jams, performing routine maintenance, or operating machinery under time pressure. If the manufacturer could anticipate how the machine would realistically be used in the workplace, it had a duty to warn about the associated risks.

Do manufacturers have to warn about dangers discovered after the machine is sold?

Yes. Manufacturers have a continuing duty to warn when they later learn their product poses serious dangers. This may include issuing updated warnings, safety notices, recalls, or retrofit instructions. Failing to act after discovering post-sale hazards can expose manufacturers to significant liability.

What if warning labels were present but unclear or easy to miss?

Warnings can be legally inadequate even if they exist. A warning may fail if it is:

- Too small or poorly placed

- Written in overly technical language

- Buried in a manual instead of on the machine

- Missing visual symbols or pictograms

- Inconsistent with how the machine is actually used

The law looks at whether the warning was reasonably calculated to catch the user’s attention and prevent injury.

Can I still recover compensation if I was partly at fault?

In many product liability cases, yes. Even if your actions contributed to the injury, manufacturers can still be held responsible for defective warnings. Comparative fault rules may reduce recovery, but they do not automatically bar compensation, especially when the injury stems from a dangerous, undisclosed risk.

What injuries are common in failure-to-warn cases?

These cases frequently involve:

- Amputations

- Crushing injuries

- Severe hand, arm, or limb trauma

- Electrocutions

- Burns

- Permanent disability

The more severe the injury, the more closely courts scrutinize whether adequate warnings were provided.

How long do I have to file a failure-to-warn lawsuit?

Time limits vary by state and case type. In many situations, strict deadlines apply, and delay can jeopardize your claim. Speaking with an experienced product liability attorney as soon as possible helps preserve evidence and protect your rights.

How can WIN Injury & Accident Trial Lawyers help?

We investigate whether manufacturers knew—or should have known—about dangerous risks and failed to warn users. Our team works with engineering experts, reviews internal corporate documents, and aggressively pursues compensation for medical bills, lost income, and long-term harm.