Industrial machines are meant to improve productivity, reduce physical strain, and create safer workplaces. But when a machine is dangerous by design, even the most careful worker, the best training program, and perfect manufacturing quality cannot eliminate the risk. In these situations, the danger is built into the machine itself.

A design defect exists when a machine is inherently unsafe—even when it is manufactured exactly as intended and used exactly as the manufacturer expected. These cases are especially serious because the problem is not a one-off error or a rogue component. Every unit built according to that design carries the same hidden danger, exposing every worker who uses it to the same risk.

At WIN Injury & Accident Trial Lawyers, we represent workers who have suffered catastrophic injuries because manufacturers chose unsafe designs over safer alternatives. These cases often involve amputations, crushing injuries, severe hand and arm trauma, and permanent disability—injuries that forever change a worker’s life and livelihood. In many instances, the harm could have been prevented with relatively simple and well-known safety design choices.

What Is a Design Defect?

A design defect occurs when the overall concept, layout, or engineering of a machine creates an unreasonable risk of harm, regardless of how carefully the machine was built or how responsibly it was used. The focus is not on mistakes in assembly or isolated defects, but on the blueprint itself.

This is what distinguishes design defects from manufacturing defects. A manufacturing defect affects a specific unit because something went wrong during production. A design defect, by contrast, affects every machine made under the same design, meaning the danger is systemic, not accidental.

Courts analyze design defect claims by asking whether the machine’s risks outweigh its benefits when compared to safer alternatives. The core legal question is simple but powerful:

Could the manufacturer have designed the machine more safely without destroying its usefulness or making it unreasonably expensive?

If a safer alternative design existed—and was technologically and economically feasible—then the original design may be legally defective.

Why Design Defect Cases Are So Important

Design defect cases strike at the heart of product safety. When manufacturers cut corners at the design stage, they often expose thousands of workers to the same hazard across factories, job sites, and processing plants nationwide. Unlike warning or training failures, design defects cannot be fixed by telling workers to “be more careful.” The danger remains until the design itself is changed.

These cases force manufacturers to answer difficult questions about their priorities:

- Did they choose a cheaper design over a safer one?

- Did they ignore known engineering solutions to increase profits or productivity?

- Did they rely on workers to adapt to dangerous machines instead of designing machines to protect workers?

Holding manufacturers accountable for unsafe designs not only compensates injured workers—it also drives safer engineering decisions that protect future workers from the same fate.

At WIN Injury & Accident Trial Lawyers, we pursue design defect cases with the understanding that the safest machine is one that does not rely on luck, perfect behavior, or constant vigilance to prevent injury. When a machine is unsafe by design, the responsibility belongs where it started—with the manufacturer.

Common Examples of Dangerous Design Defects

Design defect cases frequently arise in industrial, manufacturing, construction, and food-processing environments, where workers interact with powerful machinery on a daily basis and depend on thoughtful engineering for their safety. In these settings, injuries often occur not because a worker made a mistake, but because the machine was engineered in a way that exposed workers to unnecessary and preventable danger.

Below are some of the most common unsafe design choices we see in serious injury cases—and why they matter.

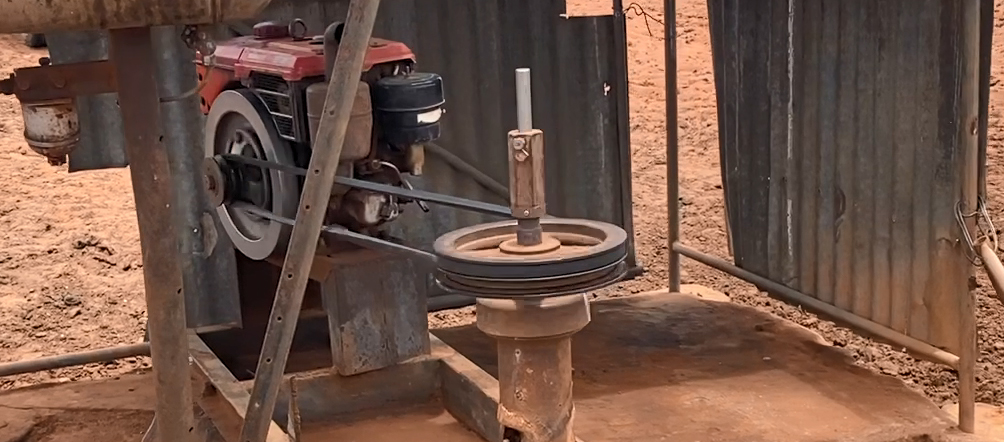

⚠️ Lack of Proper Guarding

Machines with exposed gears, rollers, belts, presses, or blades create an extreme risk of amputation, crushing, and entanglement injuries. Manufacturers may be liable when equipment is designed without:

- Physical guards that shield moving or rotating parts

- Interlocked guards that automatically shut the machine down when opened

- Fixed barriers or distance guards that prevent hands, arms, or clothing from entering danger zones

When guarding is absent—or designed in a way that allows easy bypass—the danger is no longer incidental. The design itself invites injury, especially during routine tasks like clearing jams or repositioning materials.

⚠️ Unsafe Placement of Controls

A machine can also be defectively designed when its controls force workers into harm’s way. Requiring an operator to reach across hazardous areas to start, stop, or adjust equipment is a well-recognized safety failure.

Common examples include:

- Emergency stop buttons located too far from the operator

- Control panels positioned near pinch points or blades

- Interfaces requiring two hands in close proximity to danger zones

Safer alternatives—such as remote controls, repositioned interfaces, or two-hand control systems—are widely known in safety engineering. When manufacturers ignore these options to save space or cost, the risk shifts directly onto workers.

⚠️ No Safe Method for Maintenance, Cleaning, or Adjustments

Many of the most devastating injuries occur outside of normal machine operation, during maintenance, cleaning, or troubleshooting. These tasks are foreseeable and unavoidable, yet often ignored during the design phase.

A design defect may exist when machines:

- Cannot be serviced without exposing workers to moving parts

- Require guards to be removed for routine cleaning or adjustments

- Lack safe access points or lockout-compatible designs

Manufacturers are legally required to anticipate that machines will need regular servicing. Designing equipment that can only be maintained dangerously is not an accident—it is often a fundamental design failure.

⚠️ Failure to Include Redundant Safety Features

Modern safety engineering relies on redundancy—the principle that no single failure should result in catastrophic harm. When machines lack backup safety systems, even minor malfunctions can lead to severe injuries.

Design defects in this category may involve failure to include:

- Dual shut-off or emergency stop systems

- Safety interlocks that prevent operation under unsafe conditions

- Sensors that detect human presence, guard removal, or abnormal operation

When one failed switch, sensor, or human error can directly cause a life-altering injury, the design may be unreasonably dangerous.

⚠️ Designs That Invite Foreseeable Misuse

Manufacturers cannot escape liability by blaming workers for behavior that is predictable in real-world conditions. A machine may be defectively designed if it invites or encourages unsafe conduct in order to function efficiently.

Examples include:

- Guards that are easy to remove and difficult to reinstall

- Designs that slow production unless safety features are bypassed

- Equipment that frequently jams unless operated unsafely

Courts recognize that workers operate under time pressure, productivity demands, and real-world constraints. If misuse is foreseeable, the manufacturer has a duty to design against it—not rely on perfect behavior to avoid injury.

In design defect cases, the common thread is this: the danger was built into the machine from the start. When safer design choices were available but ignored, manufacturers can—and should—be held accountable for the harm that follows.

How Courts Evaluate Design Defect Claims

Design defect cases focus on the choices made at the design stage, long before a machine ever reaches the factory floor or job site. Courts do not ask whether a machine could have been made perfectly safe. Instead, they evaluate whether the manufacturer unreasonably exposed users to danger by failing to adopt safer design alternatives that were available at the time.

At the heart of these cases is the question of reasonable safety.

Courts commonly examine whether:

- A safer alternative design would have reduced or eliminated the risk without undermining the machine’s core function. If a design change could have prevented the injury while preserving the machine’s usefulness, that weighs heavily in favor of liability.

- The alternative design was technologically feasible at the time of manufacture. Courts look at the state of engineering knowledge, existing safety technology, and whether the design solution was already known or used in the industry.

- The alternative design was economically reasonable, meaning it would not have dramatically increased cost or priced the product out of the market. Manufacturers are not excused from safety simply because a safer design costs more.

- Other manufacturers were already using safer designs, which can strongly suggest that the risk was avoidable and the safer approach was realistic—not theoretical.

The law does not demand perfection or zero risk. But it does require manufacturers to make reasonable design choices that prioritize safety over convenience, cost-cutting, or productivity at any cost. When companies ignore known safety solutions, courts are far more likely to find the design defective.

Who Can Be Held Liable for a Design Defect?

Design defect liability often extends beyond a single company. Because the danger originates in the design process, multiple entities involved in creating, supplying, or modifying the machine may share responsibility.

Depending on the facts, liable parties may include:

- The original machine manufacturer, which is typically responsible for the overall design and safety features

- Companies that designed or engineered the product, including outside design firms or consultants who contributed to unsafe design decisions

- Component manufacturers, when a specific subsystem—such as a control unit, blade assembly, or safety device—was defectively designed

- Entities that modified, rebranded, or substantially altered the machine, particularly when changes removed safeguards or introduced new risks

Under strict product liability, injured workers often do not need to prove negligence, carelessness, or intent. Instead, they must show that:

- The machine’s design was defective, and

- The defect was a substantial factor in causing the injury.

This legal framework reflects a fundamental principle: manufacturers are in the best position to design safe products, and the cost of unsafe design should not be borne by the workers who suffer the consequences.

When a machine is dangerous by design, accountability should extend to every entity that helped put that danger into the marketplace.

Injured by a Dangerous Machine? We Can Help.

If you or a loved one suffered a serious injury involving industrial or commercial equipment, the machine’s design—not worker error—may be the real cause.

At WIN Injury & Accident Trial Lawyers, we work with top engineering and safety experts to prove design defects and pursue full compensation for injured workers.

Get Help From WIN Injury & Accident Trial Lawyers

Why Legal Representation Matters

Insurance companies often undervalue pain and suffering—offering minimal settlements that ignore your daily struggles. A skilled attorney can:

- Present powerful evidence of your emotional and physical suffering

- Retain expert witnesses to quantify your losses

- Use verdict data to justify higher multipliers or per diem rates

- Argue your case persuasively before a jury

At WIN Trial Lawyers, our team fights to ensure that your recovery reflects the full extent of your suffering—not just your bills.

At WIN Trial Lawyers, we know how personal injury claims can be can be. Victims often face mounting medical bills, lost wages, and emotional trauma. Our team has successfully taken on insurance companies and third parties, recovering millions for injured clients.

If you or a loved one has been injured in an accident, don’t leave your future in the hands of the insurance company. You need experienced trial lawyers who know how to prove liability and fight for maximum compensation.

If you or a loved one has been injured, don’t face this alone. The sooner you act, the stronger your case will be.

🔗 Related Posts:

Frequently Asked Questions: Design Defects in Dangerous Machinery

What is a design defect in a machine?

A design defect exists when a machine is unsafe by its very design, even if it was manufactured correctly and used as intended. In these cases, every unit made under the same design is dangerous. The issue is not a one-off error—it’s the blueprint itself.

How is a design defect different from a manufacturing defect?

A design defect affects all versions of a machine because the design is inherently unsafe. A manufacturing defect, by contrast, occurs when a particular unit deviates from an otherwise safe design due to an error during production. Design defect cases focus on safer alternatives, not isolated mistakes.

What if I was using the machine the way my employer trained me?

Employer training does not excuse a dangerous design. Manufacturers must anticipate how machines will be used in real workplaces. If a machine requires unsafe practices to operate, clean, or maintain—regardless of training—the design itself may be defective.

Can a manufacturer be liable if the machine complied with industry standards?

Yes. Compliance with industry standards or regulations does not automatically shield manufacturers from liability. Courts often find machines defective when safer alternative designs were available—even if minimum standards were technically met.

What is a “safer alternative design”?

A safer alternative design is one that would have reduced or eliminated the risk of injury without making the machine unreasonably expensive or unusable. Courts consider whether the alternative was technologically feasible and already in use by other manufacturers at the time.

Do I have a design defect claim if the machine was misused?

Possibly. Manufacturers must design machines to guard against foreseeable misuse. If the design makes it easy or tempting to bypass safety features, and that behavior is predictable in real-world conditions, the manufacturer may still be liable.

What types of injuries are common in design defect cases?

Design defect cases often involve:

- Amputations

- Crushing injuries

- Severe hand and arm trauma

- Permanent disability

- Fatal workplace accidents

The severity of these injuries often underscores how dangerous the design truly was.

Who can be held responsible for a design defect?

Liability may extend to:

- The machine manufacturer

- Designers or engineers of the equipment

- Component manufacturers

- Companies that modified or rebranded the machine

Under strict product liability, injured workers usually do not need to prove negligence—only that the design defect caused their injury.

How long do I have to file a design defect lawsuit?

Strict deadlines apply, and they vary depending on the state and type of claim. Waiting too long can permanently bar recovery. Speaking with an experienced product liability attorney as soon as possible helps preserve evidence and protect your rights.

Manufacturing Industry FAQs

What are common design defects in manufacturing equipment?

In manufacturing settings, design defects often involve unguarded moving parts, unsafe conveyor systems, poorly placed control panels, and machines that require guards to be removed for routine operation. Repetitive-motion machinery and automated systems are especially dangerous when safety interlocks or emergency shut-offs are missing or poorly designed.

What if the machine increased productivity but reduced safety?

Manufacturers cannot trade worker safety for efficiency. If a safer alternative design was available—such as automated guards or remote controls—the machine may be considered defectively designed even if it boosted output or met production goals.

Do repetitive-use machines create higher design defect risk?

Yes. Machines used continuously or at high speeds must be designed with fatigue, human error, and wear in mind. Designs that fail to account for these real-world conditions are often found defective.

Food Processing Industry FAQs

Why are design defect claims common in food processing plants?

Food processing machinery often involves blades, mixers, presses, and conveyors that require frequent cleaning. Design defects commonly arise when machines cannot be safely cleaned or sanitized without removing guards or placing workers near moving parts.

What if I was injured while cleaning or sanitizing equipment?

Injuries during cleaning are a major red flag for design defects. Manufacturers must anticipate that machines will be washed down, sanitized, and maintained regularly. If the design makes safe cleaning impossible, the machine may be defective.

Are food-grade safety standards enough to protect manufacturers?

No. Compliance with food safety or sanitation standards does not excuse unsafe mechanical design. Courts focus on whether the machine could have been designed to prevent serious injury while still meeting hygiene requirements.

Construction Industry FAQs

What design defects are common in construction machinery?

Construction equipment frequently involves design defects such as inadequate guarding, unstable platforms, poor visibility, unsafe control placement, and lack of redundant safety systems. Heavy machinery must be designed for dynamic, unpredictable job-site conditions.

What if the equipment was used on an active job site with changing conditions?

Manufacturers must design construction equipment with foreseeable job-site realities in mind, including uneven terrain, weather exposure, and multiple workers operating nearby. Designs that fail under normal construction conditions may be defective.

Can rental or modified construction equipment still be defective by design?

Yes. Even if equipment is rented or modified, manufacturers and designers may still be liable if the original design lacked essential safety features or made safe operation unrealistic in the field.

How can WIN Injury & Accident Trial Lawyers help?

At WIN Injury & Accident Trial Lawyers, we partner with engineering experts to identify dangerous designs, prove safer alternatives, and hold manufacturers accountable. We fight for full compensation—and safer machines for everyone.