Amputation injuries are among the most devastating outcomes of industrial and workplace accidents. When a machine fails, malfunctions, or lacks proper safety features, the consequences can be permanent—resulting in the loss of a hand, arm, leg, foot, fingers, or toes in a matter of seconds.

If your amputation injury was caused by defective machinery, you may have the right to sue the manufacturer, in addition to receiving workers’ compensation benefits. These product-liability claims often result in significantly higher compensation than workers’ comp alone.

At WIN Trial Lawyers, we represent workers and families in catastrophic injury cases involving defective equipment and fight to hold manufacturers fully accountable.

How Defective Machinery Causes Amputation Injuries

Industrial machines are designed to perform powerful, repetitive, and often hazardous tasks at high speeds. While these machines are essential to industrial operations, they must also include adequate safety protections to prevent catastrophic injuries. When manufacturers cut corners, ignore known risks, or fail to provide proper warnings and safeguards, the risk of amputation increases dramatically.

Many machinery-related amputations occur not because workers were careless, but because the equipment itself was unreasonably dangerous when used as intended—or in ways the manufacturer should have anticipated.

Common scenarios include:

- Exposed moving or rotating parts, such as belts, gears, rollers, or blades that can pull in clothing, hands, or limbs

- Machines that start unexpectedly, often due to faulty controls, electrical defects, or inadequate lockout/tagout design

- Failure of emergency shut-off systems, leaving workers unable to stop the machine once a dangerous condition arises

- Missing or inadequate safety guards, allowing direct access to pinch points and cutting mechanisms

- Design flaws that make safe operation impossible, such as requiring workers to place their hands near moving parts to perform routine tasks

These failures frequently occur in manufacturing plants, warehouses, construction sites, refineries, and agricultural operations, where machines are used continuously and under pressure to meet production demands. In many cases, manufacturers are aware of these risks but fail to correct them or provide adequate warnings.

Types of Machinery Commonly Involved in Amputation Injuries

Amputation injuries most often involve heavy, high-powered, or automated equipment that operates with significant force and speed. These machines leave little margin for error when safety systems fail.

Common machinery involved in amputation injuries includes:

- Conveyor belts and material-handling systems, which can entangle limbs or pull workers into machinery

- Presses, stamping machines, and punch presses, frequently associated with finger, hand, and arm amputations

- Forklifts and powered industrial trucks, which can cause crushing amputations in collisions or tip-over incidents

- CNC machines, lathes, and milling equipment, where rotating components and cutting tools pose extreme risks

- Industrial saws and grinders, capable of causing instantaneous and severe limb loss

- Robotic arms and automated assembly lines, which may move unexpectedly or fail to detect nearby workers

In many cases, these machines are inherently dangerous and require strict safety measures, including proper guarding, redundant shut-off systems, clear warnings, and comprehensive training. When these protections are missing or defective, the likelihood of a life-altering amputation injury increases substantially. strict adherence to safety standards.

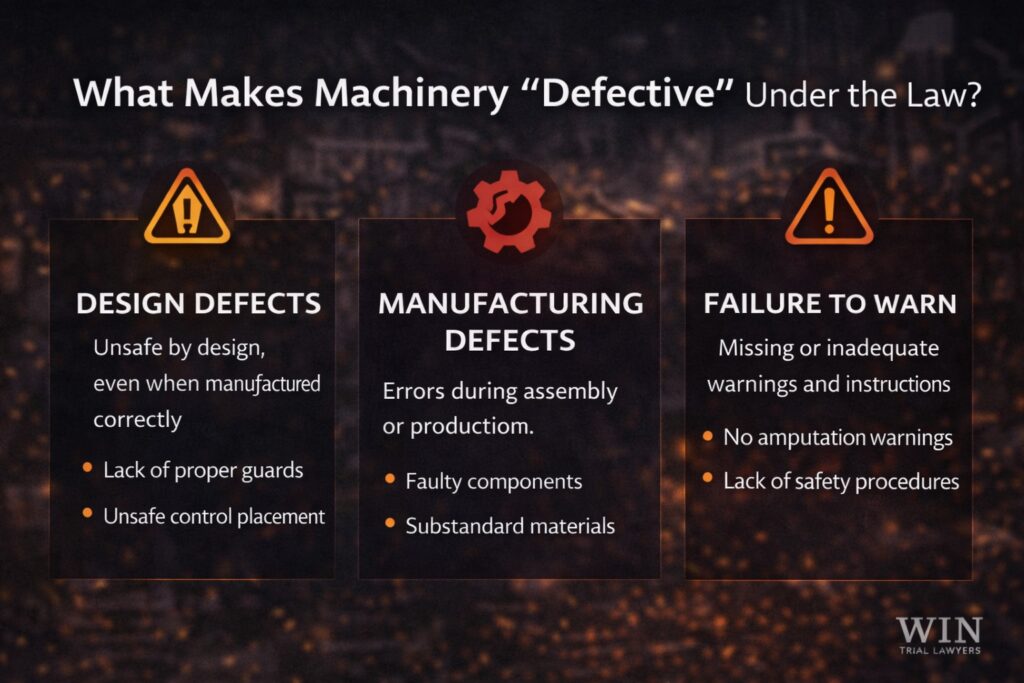

What Makes Machinery “Defective” Under the Law?

Manufacturers can be held legally responsible when machinery is defective under product liability law, even if they did not act intentionally or recklessly. Unlike ordinary negligence claims, product liability focuses on the condition of the product itself, not the conduct of the injured worker.

A machine may be considered legally defective when it is unreasonably dangerous and causes injury during foreseeable use. In amputation cases, defects often fall into one or more of the following categories.

1. Design Defects

A design defect exists when the machine is unsafe by design—even when manufactured correctly and used as intended. In these cases, every version of the machine is dangerous, not just one faulty unit.

Examples include:

- Lack of proper guarding, allowing workers to come into contact with moving or rotating parts

- Unsafe placement of controls, requiring operators to reach across hazardous areas

- No safe method to perform routine maintenance, cleaning, or adjustments

- Failure to include redundant safety features, such as dual shut-off systems

- Designs that invite foreseeable misuse, such as making guard removal easy or tempting

In design defect cases, the focus is on whether a safer alternative design was available and feasible at the time the machine was made.

2. Manufacturing Defects

A manufacturing defect occurs when the machine deviates from its intended design due to errors during production, assembly, or quality control. Unlike design defects, manufacturing defects typically affect individual units or batches, not every machine.

Common examples include:

- Faulty or missing components, such as malfunctioning sensors or emergency stops

- Improper assembly, leading to loose parts or unstable components

- Substandard materials, causing parts to break, wear down, or fail prematurely

- Electrical defects, resulting in unexpected startups or failures

Even if a machine was designed safely, a manufacturing defect can make it dangerously unpredictable and prone to causing catastrophic injuries.

3. Failure to Warn or Inadequate Instructions

A machine may also be considered defective if the manufacturer failed to provide adequate warnings or instructions about known dangers. This includes failing to warn about risks that are not obvious to the average user.

Examples include failure to warn about:

- Risks of amputation or crushing injuries

- Required safety procedures, including lockout/tagout protocols

- Proper use, maintenance, and inspection procedures

- Known hazards discovered after the machine was sold

Manufacturers have a duty to warn users not only at the time of sale, but also when they later become aware of serious dangers associated with their products.

What You Do Not Have to Prove

In product liability cases, you do not need to prove negligence in the traditional sense. You do not have to show that the manufacturer intended harm or acted carelessly.

Instead, you must show that:

- The machinery was defective

- The defect made the machine unreasonably dangerous

- The defect caused or contributed to your amputation injury

This legal framework is particularly important in catastrophic injury cases, where manufacturers often try to shift blame to workers or employers.

Can You Sue the Manufacturer if You’re Receiving Workers’ Compensation?

Yes. While workers’ compensation generally prevents lawsuits against your employer, it does not protect machine manufacturers or other third parties.

This means you can:

- Receive workers’ compensation benefits for medical care and wage replacement

- File a product liability lawsuit against the manufacturer (and others) for full civil damages

This dual-claim strategy is often essential in catastrophic injury cases.

What Compensation Is Available in a Product Liability Amputation Case?

Unlike workers’ compensation, a product liability lawsuit against a machinery manufacturer allows an injured worker to pursue full civil damages—designed to account for the lifelong physical, emotional, and financial consequences of an amputation injury.

These cases focus not only on what you’ve already lost, but also on the long-term impact the injury will have on your ability to live, work, and function independently.

Recoverable damages may include:

- Pain and suffering, reflecting the physical pain, discomfort, and ongoing limitations caused by the amputation

- Emotional distress and psychological trauma, including anxiety, depression, PTSD, and adjustment disorders commonly associated with limb loss

- Loss of enjoyment of life, compensating for the inability to participate in activities, hobbies, or daily tasks you once enjoyed

- Full wage loss and future earning capacity, including diminished ability to work in your prior occupation or advance in your career

- Lifetime medical care, such as surgeries, rehabilitation, physical therapy, and follow-up treatment

- Prosthetics and assistive devices, including replacements, upgrades, and ongoing maintenance over a lifetime

- Home and vehicle modifications, such as ramps, widened doorways, adaptive vehicles, or specialized equipment

- Out-of-pocket expenses, including transportation, caregiving assistance, and medical supplies

- Punitive damages, in cases involving extreme negligence, willful safety violations, or reckless disregard for human safety

In serious amputation cases, these damages often reach hundreds of thousands—or even millions—of dollars, particularly when the injury affects a dominant limb, prevents a return to work, or requires lifelong medical and prosthetic care.

Because manufacturers and insurers aggressively dispute the value of these claims, thorough documentation, expert testimony, and experienced legal representation are critical to ensuring that the full scope of damages is recognized and fairly compensated.

Why Amputation Cases Against Manufacturers Are Complex

Product-liability amputation cases are highly technical and aggressively defended. Manufacturers often claim:

- The machine was misused

- Safety features were removed by the employer

- The injury was caused by operator error

Successfully proving a defective machinery case requires:

- Preservation of the machine and components

- Engineering and safety expert analysis

- Review of design specifications and prior incidents

- OSHA and Cal/OSHA investigation records

- Coordination with workers’ compensation claims

These cases demand experienced trial lawyers with the resources to take on large corporations.

Deadlines Matter

Strict time limits apply:

- Workers’ Compensation: Report within 30 days and file within one year

- Product Liability Lawsuit: Generally two years from the date of injury (shorter if a public entity is involved)

Missing a deadline can permanently bar your claim.

Get Help After a Machinery-Related Amputation Injury

If you or a loved one suffered an amputation injury caused by defective machinery, the stakes are too high to leave your case to chance.

At WIN Trial Lawyers, we work with engineers, safety experts, and medical professionals to build powerful product-liability cases—while coordinating with workers’ compensation counsel to maximize total recovery.

Free Consultation

No Fees Unless We Win

Trial Lawyers for Catastrophic Injury Cases

Contact WIN Trial Lawyers today to protect your rights and your future.

Get Help From WIN Injury & Accident Trial Lawyers

Why Legal Representation Matters

Insurance companies often undervalue pain and suffering—offering minimal settlements that ignore your daily struggles. A skilled attorney can:

- Present powerful evidence of your emotional and physical suffering

- Retain expert witnesses to quantify your losses

- Use verdict data to justify higher multipliers or per diem rates

- Argue your case persuasively before a jury

At WIN Trial Lawyers, our team fights to ensure that your recovery reflects the full extent of your suffering—not just your bills.

At WIN Trial Lawyers, we know how devastating distracted driving accidents can be. Victims often face mounting medical bills, lost wages, and emotional trauma. Our team has successfully taken on insurance companies and distracted drivers, recovering millions for injured clients.

If you or a loved one has been injured in a speeding-related car accident, don’t leave your future in the hands of the insurance company. You need experienced trial lawyers who know how to prove liability and fight for maximum compensation.

If you or a loved one has been injured in a distracted driving accident, don’t face this alone. The sooner you act, the stronger your case will be.

🔗 Related Posts:

Frequently Asked Questions About Amputation Injuries From Defective Machinery

Can I sue a machine manufacturer if I lost a limb at work?

Yes. While workers’ compensation usually prevents lawsuits against your employer, it does not protect machine manufacturers. If defective machinery caused your amputation, you may be able to file a product liability lawsuit against the manufacturer.

What makes machinery legally “defective”?

Machinery may be defective due to:

- Design defects (unsafe design even when used properly)

- Manufacturing defects (errors during assembly or production)

- Failure to warn (missing or inadequate safety warnings or instructions)

You do not have to prove negligence—only that the defect caused your injury.

Can I still sue if my employer removed safety guards?

Possibly, yes. Manufacturers often argue that safety features were removed, but liability may still exist if:

- The machine was unsafe even with guards

- The design made guard removal foreseeable

- Warnings were inadequate

- The machine failed to prevent dangerous misuse

These cases require detailed investigation and expert analysis.

Can I receive workers’ compensation and sue the manufacturer at the same time?

Yes. You can receive workers’ compensation benefits for medical care and wage replacement while also pursuing a product liability lawsuit against the manufacturer for full civil damages.

What damages can I recover in a machinery amputation lawsuit?

A product liability claim may allow recovery for:

- Pain and suffering

- Emotional distress and trauma

- Loss of enjoyment of life

- Full wage loss and future earning capacity

- Lifetime medical care and prosthetics

- Home and vehicle modifications

- Punitive damages in extreme cases

These damages often far exceed workers’ compensation benefits.

What if I was partially at fault for the accident?

In product liability cases, fault is often less important than the defect itself. Even if mistakes were made, manufacturers may still be liable if the machine was unreasonably dangerous or lacked proper safeguards.

Do OSHA or Cal/OSHA violations matter in these cases?

Yes. OSHA or Cal/OSHA findings can be powerful evidence showing unsafe conditions, failure to guard machinery, or prior knowledge of hazards. While these agencies don’t compensate victims, their findings often strengthen civil lawsuits.

How long do I have to file a lawsuit against the manufacturer?

In California, product liability lawsuits generally must be filed within two years of the injury. Workers’ compensation claims have separate deadlines. Missing either deadline can permanently bar recovery.

Why are defective machinery amputation cases so complex?

These cases involve technical evidence, engineering experts, safety standards, and aggressive defense teams from manufacturers. Preserving the machine and investigating early are critical.

Do I need a lawyer experienced in product liability cases?

Yes. Defective machinery cases are not routine injury claims. An experienced trial lawyer with product liability expertise can preserve evidence, retain experts, and pursue maximum compensation.

When should I contact an amputation lawyer?

You should contact an amputation lawyer as soon as possible after the injury. Early involvement helps preserve evidence, secure the machinery involved, identify responsible manufacturers or third parties, and protect critical deadlines that can affect your ability to recover full compensation.

What does an amputation lawyer do that workers’ compensation doesn’t?

An amputation lawyer investigates whether parties outside your employer—such as machine manufacturers, maintenance companies, or contractors—can be held liable. Unlike workers’ compensation, an amputation lawyer can pursue damages for pain and suffering, emotional distress, future earning capacity, and lifetime medical needs.

How can an amputation lawyer prove machinery was defective?

An experienced amputation lawyer works with engineers, safety experts, and product-design specialists to analyze the machine, review safety standards, examine prior incidents, and determine whether the equipment had design defects, manufacturing defects, or inadequate warnings that caused the injury.

Is it expensive to hire an amputation lawyer?

Most amputation lawyers, including WIN Trial Lawyers, work on a contingency fee basis, meaning you pay nothing upfront and no legal fees unless compensation is recovered for you.

Do I need an amputation lawyer if the manufacturer denies responsibility?

Yes. Manufacturers aggressively defend these cases and often blame workers or employers. An experienced amputation lawyer knows how to counter these defenses, preserve evidence, and build a case that holds manufacturers accountable.